Double cone Blender Machine | High-Precision | GMP Model for Pharma & Food Industries

Proven Choice of Pharmaceutical, Nutraceutical & Food Manufacturers for 10 Years

Custom-built double cone blender machines designed for gentle yet efficient tumbling action, ensuring uniform blending, excellent material flow, and minimal product degradation—ideal for free-flowing powders and granules.

- Capacity: Lab models to 5000 kg industrial scale

- SS316 / SS304 Food-grade stainless steel

- Precise speed control for uniform mixing

- Safety inter-lock & digital timer

- Best for Pharma, Nutraceutical & Food industries

Ready to scale your Powder Mixing?

Get a personalized quote for the Double cone blender model that fits your needs. Our team replies within 24 hours with recommendations and pricing.

Laboratory scale double cone blender

Compact laboratory model for R&D and small trial batches. Ideal for product development and sampling.

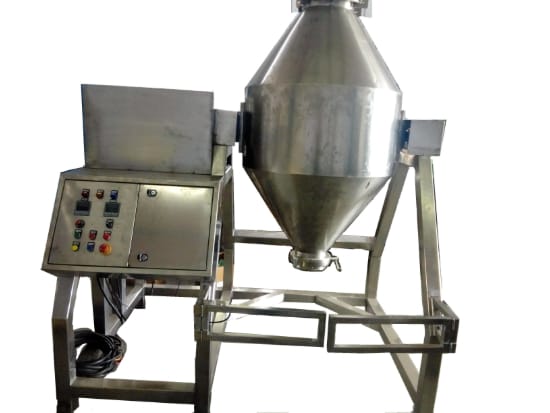

Production scale double cone blender

Heavy-duty industrial model, scalable up to 5000 kg batch capacity. Perfect for pharmaceutical, food & chemical industries.

Why choose Our Double cone Blender Machines ?

Trusted by pharmaceutical, nutraceutical & food manufacturers worldwide for precision and performance

Precision Mixing

Variable bin speed and controlled motion ensure uniform, repeatable blending for powders and granules.

GMP Hygienic Design

Constructed in food-grade SS316 / SS304 with smooth surfaces and easy-clean geometry to meet strict GMP standards.

Scalable Capacity

From laboratory models for R&D to production units scalable up to 5000 kg batch capacity — pick the size you need.

Built to last

Robust stainless construction and high-quality components deliver long service life and minimal downtime.

Energy Efficient

Optimised motor selection with VFD control reduces power consumption without compromising mixing performance.

Easy Maintenance

Tool-free access panels, modular parts and quick-disconnect fittings make servicing fast and cost-effective.

double cone blender Models and Specifications

Four specialized models designed to meet every scale of powder mixing.

cGMP-compliant designs | SS316 contact parts | Custom configurations available

Lab Double Cone Blender

Available in 2 kg, 5 kg & 10 kg. Compact, portable, best for trial batch and testing.

100 kg Double Cone Blender

GMP model with gross volume of 300 L, best suitable for 100 kg per batch production

200 kg Double Cone Blender

GMP model with gross volume of 600 L, best suitable for 200 kg per batch production

500 kg Double Cone Blender

GMP model with gross volume of 1500 L, best suitable for 500 kg per batch production

Machine Specifications

Typical technical specifications for standard double cone blender machines.

| Sr. No. | Gross Volume (L) | Working capacity (kg) | Product Contact Parts | Non-Contact Parts | Main Motor Power (HP) | Overall Dimensions (mm) | Machine Weight (kg) | Power Supply | Avg. Power Consumption (kWh) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 6, 15, 30 | 2, 5, 10 | SS316 | SS304 | 0.5 | 3000x600x800 | 70 | Single Phase | 0.37 |

| 2 | 300 | 100 | SS316 | SS304 | 2 | 1200×900×1250 | 190 | Three Phase | 1.5 |

| 3 | 600 | 200 | SS316 | SS304 | 3 | 1300×1100×1300 | 300 | Three Phase | 2.2 |

| 4 | 1500 | 500 | SS316 | SS304 | 10 | 1600×1200×1700 | 760 | Three Phase | 7.5 |

Specifications may vary depending on material bulk density, product characteristics, and customer-specific customization requirements.

Lab Scale Double Cone Blender

- Model: cGMP and Non-GMP (Optional)

- Batch capacity: 2 kg to 10 kg

- Container gross volume: 5 ltr to 25 ltr

- Product contact parts: SS316L

- Non-contact parts: SS304 or MS cladded with SS304

- Motor: 0.5 HP, Single Phase

- Safety railing with interlock

- Discharge: TC Ended or Butterfly valve

- Customized machines available on request

300 Ltr Gross Volume Double Cone Blender

- Model: cGMP and Non-GMP (Optional)

- Batch capacity: 100 kg

- Container gross volume: 300 L

- Product contact parts: SS316L

- Non-contact parts: SS304 or MS cladded with SS304

- Motor: 2 HP, Three Phase

- Safety railing with interlock

- Discharge: 6 inch manually operated Butterfly valve

- Customized machines available on request

600 Ltr Gross Volume Double Cone Blender

- Model cGMP and Non-GMP (Optional)

- Batch capacity: 200 kg

- Container gross volume: 600 L

- Product contact parts: SS316L

- Non-contact parts: SS304 or MS cladded with SS304

- Motor: 3 HP, Three Phase

- Safety railing with interlock

- Discharge: 6 inch manually operated Butterfly valve

- Customized machines available on request

1500 Ltr Gross Volume Double Cone Blender

- Model cGMP and Non-GMP (Optional)

- Batch capacity: 500 kg

- Container gross volume: 1500 L

- Product contact parts: SS316L

- Non-contact parts: SS304 or MS cladded with SS304

- Motor: 10 HP, Three Phase

- Safety railing with interlock

- Discharge: 10 inch manually operated Butterfly valve

- Customized machines available on request

Double cone Blender Machine – Frequently Asked Questions (FAQ)

What is a Double Cone Blender and what is its primary function?

How does the Double Cone Blender machine work to achieve a uniform mix?

What are the key advantages of this design for sensitive dry powders?

What is the typical capacity range for the Double Cone Blenders manufactured by Wecan?

What industries most commonly use the Double Cone Blender for their mixing needs?

What materials of construction are used to manufacture these blenders for quality assurance?

What motor power options and gearboxes are available for the different blender capacities?

What safety features and design elements are integrated into the Double Cone Mixer?

Can the Double Cone Blender be customized with automation and special handling features?

Who is the manufacturer of this equipment, and what is your expertise in industrial mixers?

double cone Blender – Working & Trial Videos

Lab Scale Double Cone Blender

Lab Scale Double Cone Blender

Double Cone Blender

Non GMP Double Cone Blender

cGMP Double Cone Blender

double cone blender mixer machine working principle

Working Principle of Double Cone Blender Mixer Machine

The double cone blender operates on a simple yet effective principle to achieve uniform mixing of dry powders and granules. The conical-shaped vessel rotates on its horizontal axis, and this vessel mounts on trunnions at either end, allowing for smooth and efficient rotation. As the blender rotates, the material inside continuously splits and recombines, leading to a uniform mix.

- Loading: Operators load the dry powders or granules into the blender through a butterfly valve or a charging port. Typically, the loading amount ranges between 35% to 70% of the blender’s total capacity, ensuring efficient mixing without overloading the machine.

- Rotation: Once loaded, the blender starts rotating. The conical shape of the vessel creates a tumbling action, causing the materials to move in different directions. As a result, this continuous movement helps break up clumps and ensures that the materials mix uniformly.

- Mixing: The mixing process involves two key actions:

- Convective Mixing: The rotation causes the materials to cascade and flow, thereby promoting convective mixing.

- Diffusive Mixing: As the materials tumble, they also undergo diffusive mixing, where individual particles move randomly, leading to a more homogeneous blend.

- Discharge: After the desired mixing time, operators stop the blender and discharge the mixed material through a bottom outlet or a discharge valve. The design of the double cone blender ensures minimal residue, thus making the discharge process efficient and easy to clean.

- Advantages:

- Gentle Mixing: The double cone blender provides a gentle mixing action, preventing product degradation and maintaining the quality of sensitive materials.

- Homogeneous Mix: The unique design and tumbling action ensure a uniform and consistent blend.

Overall, the double cone blender offers an efficient, reliable, and versatile solution for mixing dry powders and granules in various industries.

Double cone blender mixer machine by wecan engineering solutions, a leading machine manufacturer in India

Double Cone Blender Manufacturer in India: Wecan Engineering Solutions

Wecan Engineering Solutions, based in Kathlal, Kheda, Gujarat, manufactures high-quality double cone blenders and other industrial mixing equipment. We established our company in 2012, and since then, we have focused on developing innovative, high-tech products that conform to the latest industry trends.

Our double cone blenders efficiently mix pharmaceutical, food, and nutraceutical products. Consequently, these machines ensure uniform blending and meet the highest standards of quality and reliability.

Why Choose Us:

- Expertise: We bring over a decade of experience in manufacturing high-quality industrial mixers. Furthermore, our team’s extensive knowledge ensures that our products are top-notch.

- Quality Assurance: We commit to delivering machines that assure optimum quality in manufactured products. As a result, our clients can rely on the consistency and durability of our equipment.

- Innovation: We continuously develop new and improved products to meet industry needs. Therefore, our innovations keep our clients ahead of the competition.

For more information or to discuss your specific requirements, please visit our website at https://www.wecanmachinery.com or contact us directly at [email protected]

Production Scale double cone Blender – Machine Video & Product Catalogue

Double cone blenders efficiently mix and blend dry powders and granules in various industries, such as pharmaceuticals, food, and chemicals. Their unique double cone shape ensures uniform distribution of ingredients by continuously rotating and tumbling the materials. Consequently, you achieve a homogeneous mix every time. Made from high-grade stainless steel, these blenders offer robust construction and easy cleaning. Furthermore, they feature capacities ranging from several hundred to several thousand liters, making them suitable for large-scale production. Additionally, the gentle mixing action prevents product degradation while maintaining the quality and consistency of the blend. Overall, double cone blenders serve as ideal solutions for high-volume manufacturing processes.

laboratory Scale double cone Blender – Machine Video & Product Catalogue

Lab-scale double cone blenders efficiently mix and blend small quantities of dry powders and granules, particularly in laboratory settings for pharmaceuticals, food, and chemicals. Their unique double cone shape ensures uniform distribution of ingredients by continuously rotating and tumbling the materials. Consequently, you achieve a homogeneous mix every time. Made from high-grade stainless steel, these blenders offer robust construction and easy cleaning. Furthermore, they feature capacities suitable for small-scale production and research purposes. Additionally, the gentle mixing action prevents product degradation while maintaining the quality and consistency of the blend. Overall, lab-scale double cone blenders serve as ideal solutions for precise and controlled mixing processes.

double cone blender machine general specifications

| Sr no | Specifications | Details |

|---|---|---|

| 1 | Capacity | 10 kg, 25 kg, 50 kg, 100 kg, 200 kg, 300 kg, 500 kg, 1000 kg, 2000 kg, 5000 kg |

| 2 | Gross Volume | 35 L, 80 L, 150 L, 300 L, 450 L, 600 L, 800 L, 900 L |

| 3 | Motor Power | 0.5 HP, 1 HP, 2 HP, 3 HP, 5 HP, 7.5 HP, 10 HP, up to 50 HP |

| 4 | Gear Box | Elecon, Redicon, CPEC, Shanthi make |

| 5 | Material | Stainless Steel (SS304, SS316) |

| 6 | Construction | Stainless Steel frames |

| 7 | Butterfly Valve | Equipped for efficient discharge |

| 8 | Safety Features | Safety guard, interlock systems, overload protection |

| 9 | Discharge Height | 300 mm, 450 mm |

| 10 | Additional Features | Dust-free bin charging system, flame-proof electricals, PLC + HMI base systems, slant design, manual rotating facility with hand wheel, polished interior and exterior surfaces, mirror polished fixed buffers inside the cone, three-phase indication, D.O.L. tarter, digital timer, Amp Meter |

application of double cone blender mixer machine

Applications of the Double Cone Blender is as under:

- In the pharmaceutical industry, operators mix excipients, active pharmaceutical ingredients (APIs), and other components to ensure a homogeneous blend, which is critical for consistent drug formulations.

- Additionally, in food processing, workers blend spices, additives, and other dry ingredients to achieve a uniform mixture, thereby enhancing the quality and flavor of food products.

- Furthermore, in the chemical industry, technicians ensure the uniform mixing of various chemical compounds, thus maintaining the consistency and effectiveness of chemical products.

- Moreover, in cosmetics, manufacturers blend cosmetic powders and other ingredients to create consistent and high-quality products like powders, creams, and lotions.

- In the same vein, personnel mix different detergent components, ensuring even distribution of active ingredients for effective cleaning products.

- Next, in fertilizer production, staff blend various components to produce a consistent mixture, which is essential for effective agricultural use.

- Also, in plastics manufacturing, engineers assist in blending plastic additives, ensuring uniform distribution in the final product, which is vital for the quality and performance of plastic items.

- Lastly, in the metallurgical industry, specialists use the blender to mix metal powders evenly, thus creating uniform and high-quality metal products.

In summary, the Double Cone Blender’s versatility, gentle mixing action, and ability to handle a wide range of materials make it an invaluable asset across these diverse industries, ensuring consistency and quality in various production processes.

double cone blender machine diagram description

Cone Blender Diagram description as under :

- Base: Place the double cone-shaped vessel horizontally.

- Motor: Attach a motor to the base to rotate the vessel.

- Loading Port: Use the top opening to add materials.

- Discharge Port: Utilize the bottom opening to remove the blended materials.

- Control Panel: Adjust the rotation speed and other parameters using the control panel.

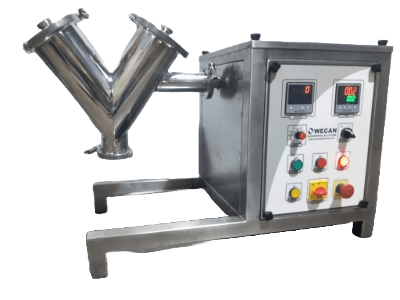

Explore alternative powder mixing solutions based on your process requirements.