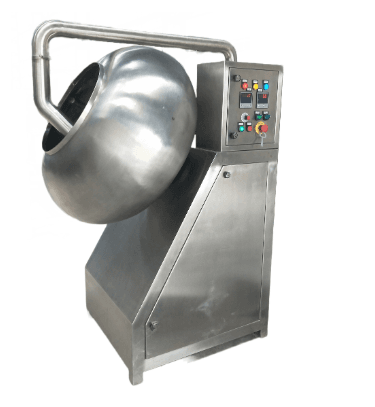

COATING PAN MACHINE

coating pan machine - process

COATING PAN MACHINE FUNDAMENTAL

- The masala coating pan machine plays a crucial role in the food industry for applying coatings to fried food products. Initially, operators load the products into the rotating drum. As the drum rotates, the products tumble, allowing an even distribution of the seasoning solution. Simultaneously, the spray system applies the masala coating, while the air handling system controls temperature and humidity for effective drying. Therefore, the machine provides uniform, high-quality coatings, enhancing product flavor, appearance, and consistency.

- Additionally, you can control parameters like drum speed, spray rate, and drying temperature, allowing precise handling of various coating tasks. Consequently, the user-friendly control system minimizes errors and optimizes production efficiency. The machine, made with high-quality materials, is durable and easy to clean, maintaining high hygiene standards. Furthermore, its robust construction ensures long-term reliability. Thus, it meets stringent industry requirements.

- Ultimately, the masala coating pan machine proves indispensable for manufacturers aiming to improve product quality and production efficiency. Moreover, its advanced features and reliable performance make it a valuable asset in any production line. Consequently, it supports various food processing applications, ensuring consistent and efficient production processes. Moreover, it adapts to different coating needs, providing flexibility. As a result, manufacturers can meet diverse market demands with high-quality, seasoned products. Therefore, it stands as a cornerstone in modern food processing, reinforcing the value of innovation and precision in production.

AVAILABLE MODELS OF COATING PAN MACHINE

- Masala Coating Machine

- Seasoning Machine

- Flavouring Machine

COATING PAN MACHINE PARTS

Here are the main parts of a coating pan machine as under :

Coating pan machine Drum (Pan): You place the food products into the rotating drum for coating. Meanwhile, the machine ensures even tumbling of the products.

Spray System: The machine sprays the masala seasoning onto the tumbling food products. Consequently, this ensures an even coating.

Air Handling System: It controls temperature and humidity to ensure effective drying of the coating. Moreover, it maintains optimal conditions inside the drum.

Exhaust System: This masala coating machine removes excess air, moisture, and solvent vapors from the drum. Thus, it keeps the environment inside the drum clean.

Control System: You monitor and adjust parameters of seasoning machine like drum speed, spray rate, and air temperature. As a result, you achieve precise control over the coating process.

Motor: It powers the rotation of the drum and the operation of the spray system. In addition, it ensures consistent performance.

Reduction Gear Box: This component reduces motor speed for consistent and reliable performance. Subsequently, it improves the overall efficiency of the machine.

Blower: It provides airflow to assist in drying the coated products. Furthermore, it enhances the drying process.

Butterfly Valve: You control the discharge of the coated products from the drum. Therefore, you can manage the output efficiently.

Heater: It maintains the required temperature for effective drying. Finally, it ensures that the coating is properly set.

These parts work together, ensuring you achieve uniform and high-quality masala coating on food products.

MASALA COATING MACHINE

SEASONING MACHINE

FLAVOURING MACHINE