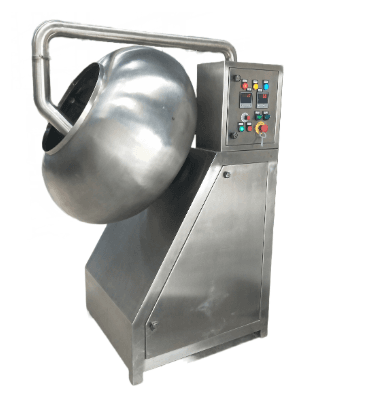

CHOCOLATE PANNING MACHINE

Chocolate Panning or coating MACHINE FOR CHOCOLATE : Discover WECAN ENGINEERING SOLUTIONs - the leading manufacturer of top-quality machines.

This Chocolate panning or coating machine for chocolate is the focus at Wecan Engineering Solutions, where we design and manufacture high-quality machines for the confectionery industry. Our machines ensure consistent and superior coating for chocolates and nuts, thanks to advanced technology and durable materials. We prioritize customer satisfaction, offering customized solutions and excellent support. With a commitment to sustainability and a global reach, We are your trusted partner for chocolate coating excellence.

AVAILABLE MACHINE SIZES

This Chocolate panning or coating machine for chocolate is a specialty at Wecan Engineering Solutions, where we design and manufacture premium machines for the chocolate industry. Additionally, we offer various models to suit different production needs, ensuring consistent and superior coating for chocolates and nuts. Our machines use advanced technology and durable materials, prioritizing customer satisfaction.

- Standard Machines:

- Large-Scale Machine:

- Customizable Machine:

- Tabletop / Small Machine:

Each chocolate panning or coating machine features high-quality materials and advanced technology to ensure durability, efficiency, and superior performance. Additionally, we support your business with reliable and innovative solutions that enhance your production process.

QUALITY OF OUR Machines

Chocolate panning or coating machine is a key focus at WECAN, where we pride ourselves on delivering machines that excel in both quality and innovation. Here’s how we ensure our machines stand out:

Superior Quality:

High-Grade Materials: We use high-quality stainless steel (SS304 or SS316) for all contact parts. Thus, ensuring durability and hygiene.

Precision Engineering: Our machines are built with meticulous attention to detail, providing reliable and consistent performance. Therefore, you can trust in their longevity and robustness.

Stringent Quality Control: We conduct rigorous testing at every stage of production. Consequently, this ensures that each machine meets our high standards before it reaches your facility.

chocolate panning or coating machine price in india

- The price of a chocolate panning or coating machine in India varies based on several factors, including the machine’s capacity, features, and the manufacturer. Typically, smaller and more basic machines cost anywhere from ₹45,000 to ₹1,50,000. Furthermore, mid-range machines offer enhanced features and greater efficiency, usually falling between ₹1,50,000 and ₹3,00,000. For large-scale industrial operations, high-end machines with advanced capabilities and larger capacities range from ₹3,00,000 and above, often reaching up to several lakhs.

- In addition, prices fluctuate based on additional features like automation, cooling systems, and the quality of materials used in the machine’s construction. Therefore, contact manufacturers directly or consult with suppliers to get precise quotes and find a machine that best suits your needs and budget. Ultimately, investing in a quality chocolate panning or coating machine significantly enhances production efficiency and product quality for confectionery businesses.

Chocolate panning or Coating Machine for chocolate WITH HOT AIR BLOWER Perfect for INDUSTRIAL USE

This chocolate panning or coating machine is for industrial use will meets the needs of large scale production businesses. Additionally, this powerful machine gives your confections a perfectly smooth and even coating, thereby enhancing their taste and visual appeal.

mini or small Chocolate panning or Coating Machine WITH BLOWER for chocolate for home USE

This mini or small chocolate panning or coating machine with inbuilt air blower for home will meets the needs of artisanal chocolatiers and small businesses. Additionally, this compact yet powerful machine gives your confections a perfectly smooth and even coating, thereby enhancing their taste and visual appeal.

mini or small Chocolate panning or Coating Machine for chocolate for home USE

This mini or small chocolate panning or coating machine for home will meets the needs of artisanal chocolatiers and small businesses. Additionally, this very compact yet powerful machine gives your confections a perfectly smooth and even coating, thereby enhancing their taste and visual appeal.