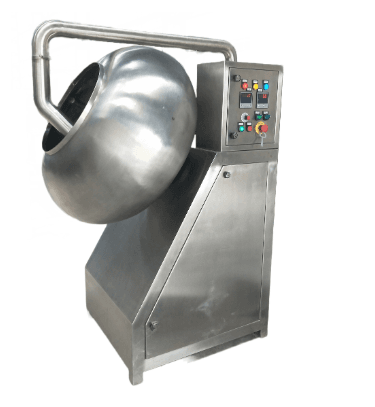

FLAVOURING MACHINE

FLAVOURING machine: Ensures even application of FLAVOURING to fried foods, enhancing flavor and quality.

A flavouring machine uniformly applies flavouring to fried food products. First, you place the food into the rotating drum, which ensures even tumbling. Next, the machine sprays the masala while simultaneously controlling temperature and humidity for effective drying. Moreover, the user-friendly control system lets you adjust parameters like drum speed and spray rate. Additionally, built with high-quality materials, it ensures durability and easy cleaning. Consequently, this machine enhances product flavor, appearance, and consistency. Thus, it is essential for the food industry, ensuring high-quality and flavorful coatings.

We offer a wide range of models in this category. Specifically, you can choose from 2, 5, 10, 20, 30, 60 and 150 kg batch capacity options.

FLAVOURING Machine: Key Features

Ensures Uniform Coating: You can ensure an even distribution of masala on fried food products with the flavouring machine.

Rotating Drum: Meanwhile, you can use the rotating drum for consistent tumbling and uniform application.

Accurate Spray System: The flavouring machine accurately applies the masala flavouring with its spray system. Thus, it ensures even coating.

Temperature and Humidity Control: Moreover, you can control temperature and humidity to maintain optimal drying conditions. Hence, it provides high-quality results.

User-Friendly Controls: Additionally, you can easily adjust parameters like drum speed and spray rate with the user-friendly control system. Therefore, you have precise control over the process.

High-Quality Build: The flavouring machine is built with high-quality materials, ensuring durability and easy cleaning. Consequently, it lasts longer.

Adjustable Settings: Furthermore, you can adjust settings for flexibility in meeting different coating needs.

Efficient Drying: Simultaneously, the flavouring machine enhances the drying process, ensuring high-quality coatings.

Hygienic Design: Next, you can easily clean and maintain the machine, thanks to its hygienic design. Thus, it meets high sanitation standards.

Versatile Applications: Ultimately, you can use the flavouring machine for various fried food products, enhancing their flavor and appearance. Therefore, it’s highly versatile.

Reliable Performance: In addition, the flavouring machine offers reliable performance under varying conditions.

Energy Efficient: Besides, it operates efficiently, reducing energy consumption.

Compact Design: Finally, the machine’s compact design ensures it fits well in various production setups.

Cost-Effective: Subsequently, you find it to be a cost-effective solution for your coating needs.

Safety Features: Furthermore, the machine includes safety features to ensure safe operation.

These features work together to ensure you achieve uniform and high-quality flavouring on food products.

BENIFITS of FLAVOURING machine

Consistent Flavor: The flavouring machine ensures uniform coating, thereby providing a consistent and balanced flavor to all food products.

Efficiency: It speeds up the coating process, thus saving time and labor.

Enhanced Quality: This flavouring machine controls temperature and humidity for perfect coating and drying, therefore enhancing the overall quality.

Hygienic Process: It is easy to clean and maintain, hence ensuring high hygiene standards.

User-Friendly: The machine simplifies the coating process with adjustable settings and user-friendly controls, therefore making it convenient to use.

Cost-Effective: It reduces manual labor and wastage, leading to cost savings.

Versatile Applications: The machine is suitable for a wide range of fried food products, adapting to various production needs.

Reliable Performance: It is built with durable materials, ensuring long-term reliability.

Energy Efficient: The machine operates efficiently, thereby reducing energy consumption and operational costs.

Increased Production: It allows for larger batches of products to be coated in a shorter time, thereby increasing production capacity.

I hope this helps! If you need further details or have any more questions, feel free to let me know! 😊