Mass Mixer Machine | High-Precision | cGMP Model for Pharmaceutical, Nutraceutical & Food Industries

Proven Choice of Pharmaceutical, Nutraceutical & Food Manufacturers for 10 Years

Custom-built mass mixer machines engineered for intensive and uniform mixing of wet and dry materials. Designed to handle high-viscosity masses, powders, granules, and semi-solids, the machine ensures consistent blending, efficient material movement, and repeatable batch quality—ideal for pharmaceutical, nutraceutical, and food processing applications.

Capacity: Laboratory models to large industrial batches

SS316 / SS304 food-grade stainless steel contact parts

Heavy-duty paddled agitator for thorough mass mixing

Suitable for dry powders, granules, and wet mass applications

Easy cleaning and low-maintenance design

Variable speed drive, timer, and safety interlock – Optional

Designed for Pharma, Nutraceutical & Food industries

Ready to Scale Your Wet and Dry Mass Mixing?

Get a personalized quote for the mass mixer machine that fits your needs.

Our team replies within 24 hours with recommendations and pricing.

Choose your mass mixer machine

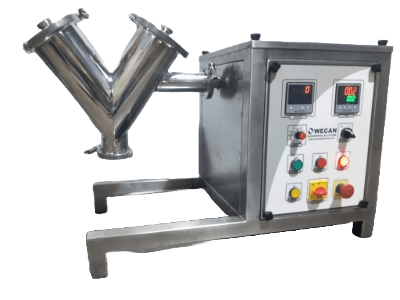

Laboratory scale mass mixer machine

Compact laboratory model for R&D and small trial batches. Ideal for formulation development, testing, and sampling.

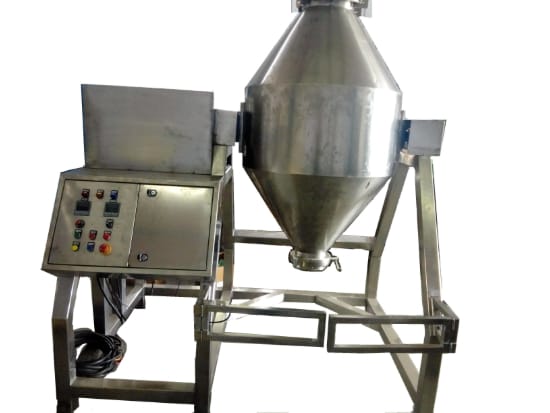

Production scale mass mixer machine

Heavy-duty industrial model with batch capacities up to 200 kg. Ideal for pharmaceutical, food, and chemical manufacturing applications.

Why choose Our Mass mixer Machines ?

Trusted by pharmaceutical, nutraceutical, and food manufacturers worldwide for precision and reliable performance.

Precision Mixing

Optimized agitator design and controlled mixing speed ensure uniform, repeatable blending of wet masses, powders, and granules.

GMP Hygienic Design

Constructed using food-grade SS316 / SS304 with smooth surfaces and easy-to-clean geometry to meet strict GMP standards.

Scalable Capacity

From laboratory models for R&D to production units scalable up to 200 kg batch capacity — pick the size you need.

Built to last

Robust stainless steel construction and high-quality components deliver long service life with minimal downtime.

Energy Efficient

Optimized motor selection with VFD control reduces power consumption without compromising mixing efficiency.

Easy Maintenance

Tool-free access panels, modular components, and quick-disconnect fittings make servicing fast and cost-effective.

Mass mixer machine Models and Specifications

Four specialized models designed to meet every scale.

cGMP-compliant designs | SS316 contact parts | Custom configurations available

Laboratory Scale Mass Mixer Machine

Available in 2 kg, 5 kg & 10 kg. Compact, portable, best for trial batch and testing.

50 kg Mass Mixer Machine

cGMP model with gross volume of 125 liter, best suitable for 50 kg per batch production.

100 kg Mass Mixer Machine

cGMP model with gross volume of 225 liter, best suitable for 100 kg per batch production.

200 kg Mass Mixer Machine

cGMP model with gross volume of 450 liter, best suitable for 200 kg per batch production.

Machine Specifications

Typical technical specifications for standard mass mixer machines.

| Sr. No. | Batch Capacity (Kg) | Contact Parts | Non Contact Parts | Motor Power (kW) | Power Supply Requirement | Mixing Type |

|---|---|---|---|---|---|---|

| 1 | 2 | SS316 | SS304 | 0.37 | Single Phase | Paddle Mixing |

| 2 | 5 | SS316 | SS304 | 0.75 | Single Phase | Paddle Mixing |

| 3 | 10 | SS316 | SS304 | 0.75 | Single Phase | Paddle Mixing |

| 4 | 50 | SS316 | SS304 | 2.2 | Three Phase | Paddle Mixing |

| 5 | 100 | SS316 | SS304 | 3.7 | Three Phase | Paddle Mixing |

| 6 | 200 | SS316 | SS304 | 7.5 | Three Phase | Paddle Mixing |

Specifications may vary depending on material bulk density, product characteristics, and customer-specific customization requirements.

Laboratory Scale Mass Mixer Machine

- Model: cGMP and Non-GMP (Optional)

- Batch capacity: 2 kg, 5 kg, and 10 kg

- Material: SS316 / SS304 (food & pharmaceutical grade)

- Motor: 0.75 kW

- Mixing bin thickness: 2.5 mm

- Top cover: Transparent polycarbonate sliding lid

- Speed control: Variable agitator speed controller – Optional

- Customization: Customized configurations available on request

50 kg Batch Capacity Mass Mixer Machine

- Model: cGMP and Non-GMP (Optional)

- Batch capacity: 50 kg

- Material: SS316 / SS304 (food & pharmaceutical grade)

- Motor: 2.2 kW

- Mixing bin thickness: 3 mm

- Top cover: Transparent polycarbonate sliding lid

- Speed control: Variable agitator speed controller – Optional

- Customization: Customized configurations available on request

100 kg Batch Capacity Mass Mixer Machine

- Model: cGMP and Non-GMP (Optional)

- Batch capacity: 100 kg

- Material: SS316 / SS304 (food & pharmaceutical grade)

- Motor: 3.7 kW

- Mixing bin thickness: 3 mm

- Top cover: Transparent polycarbonate sliding lid

- Speed control: Variable agitator speed controller – Optional

- Customization: Customized configurations available on request

200 kg Batch Capacity Mass Mixer Machine

- Model: cGMP and Non-GMP (Optional)

- Batch capacity: 200 kg

- Material: SS316 / SS304 (food & pharmaceutical grade)

- Motor: 7.5 kW

- Mixing bin thickness: 3 mm

- Top cover: Transparent polycarbonate sliding lid

- Speed control: Variable agitator speed controller – Optional

- Customization: Customized configurations available on request

Mass mixer Machine – Frequently Asked Questions (FAQ)

How Does the Mass Mixer Machine Work?

What Types of Materials Can the Mass Mixer Machine Handle?

What Are the Key Advantages of a Mass Mixer Machine?

What Batch Capacities Are Available?

How Long Does the Mixing Process Take?

Is the Mass Mixer Machine Easy to Clean and Maintain?

What Safety Features Are Provided?

Can the Mass Mixer Machine Be Customized?

Which Industries Use Mass Mixer Machines?

What Materials Are Used to Construct the Mass Mixer Machine?

Mass mixer machine – Working & Trial Videos

Mass mixer Machine – Video & Product Catalogue

A mass mixer machine is a robust industrial machine designed for efficient and uniform mixing of wet masses, powders, granules, and semi-solid materials.

It is widely used in pharmaceutical, nutraceutical, food, chemical, and cosmetic industries to achieve consistent product quality and reliable batch-to-batch performance.

Watch the machine in operation or download the detailed product catalogue to review specifications, available models, and customization options.

key features

Robust Construction: Manufactured using high-quality stainless steel (SS304 or SS316) to ensure durability, corrosion resistance, and compliance with pharmaceutical and food-grade hygiene standards.

Efficient Paddle Mixing Mechanism: Heavy-duty paddle or agitator design delivers uniform and repeatable mixing of wet masses, powders, granules, and semi-solid materials.

Wide Capacity Range: Available in laboratory and production-scale models, suitable for small trial batches as well as large-scale industrial production.

Easy Operation: User-friendly control panel enables simple operation, quick setup, and reduced operator training time.

Variable Speed Control (Optional): Adjustable agitator speed allows optimized mixing based on material characteristics and process requirements.

Safety-Focused Design: Equipped with safety interlocks, emergency stop button, and protective guarding to ensure safe and reliable operation.

mass mixer machine price in india

As a leading mass mixer machine manufacturer in India, Wecan Engineering Solutions offers a wide range of mass mixer machines designed for pharmaceutical, nutraceutical, food, and chemical applications.

The price of a mass mixer machine in India varies depending on batch capacity, model type (laboratory or production scale), material of construction, and optional features.

Typically, laboratory and small-capacity mass mixer machines start from around ₹1,15,000, while higher-capacity and fully cGMP-compliant industrial models can range up to ₹2,75,000 or more, depending on specifications.

For pharmaceutical applications requiring precise speed control, enhanced safety features, and hygienic design, pricing is generally on the higher side.

To ensure the best performance and value, it is recommended to select a mass mixer machine based on your process requirements, application type, and compliance needs.

For exact pricing and technical recommendations, please request a customized quotation based on your application.

mass mixer machine Applications

Our mass mixer machine is widely used across the following industries and applications:

Pharmaceutical Manufacturing: Wet granulation, blending of active ingredients, excipients, and bulk drug formulations.

Nutraceuticals: Mixing of vitamin blends, dietary supplements, powders, and granules.

Herbal & Ayurvedic Products: Mixing of herbal powders, extracts, and natural formulations.

Food Processing: Blending of food powders, premixes, seasonings, and functional ingredients.

Chemical & Cosmetic Industries: Mixing of chemical compounds, cosmetic powders, creams, and semi-solid formulations.