Paste Kettle Machine | High-Precision | GMP Model for Pharma & Food Industries

Proven Choice of Pharmaceutical, Nutraceutical & Food Manufacturers for Over 10 Years

Built with a cGMP-compliant design and food-grade stainless steel, the Paste Kettle Machine is engineered to deliver consistent heating and uniform agitation for preparing pastes, syrups, creams, sauces, gels, and suspensions.

Capacity Range: Laboratory models to large-scale industrial production units

Construction: SS304 / SS316 food-grade stainless steel

Heating System: Steam / electric heating with uniform heat distribution

Agitation: Anchor or scraper-type agitator for uniform, lump-free mixing

Control Panel: Digital temperature control with safety interlocks

Design Compliance: GMP & easy-to-clean hygienic construction

Applications: Pharma, nutraceutical, cosmetic & food industries

Ready to Scale Your Paste Processing?

Get a personalized quote for the Paste Kettle Machine that fits your process requirements. Our team responds within 24 hours with technical recommendations and pricing.

Choose Your Paste Kettle Model

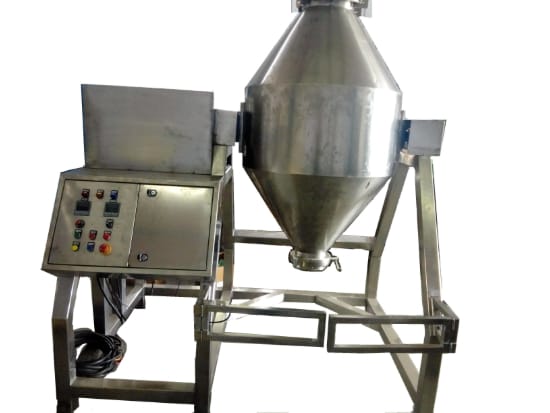

Laboratory-Scale Paste Kettle Machine

Compact laboratory model designed for R&D, pilot batches, and small trial production. Ideal for formulation development, testing, and sampling.

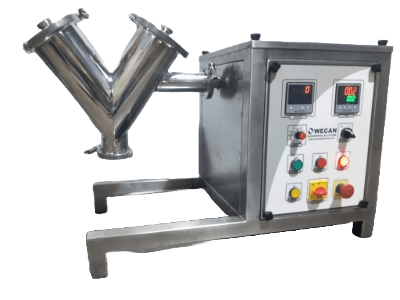

Production-Scale Paste Kettle Machine

Heavy-duty industrial model with scalable working capacity up to 100 L. Suitable for continuous production in pharmaceutical, food, and chemical industries.

Why choose Our Paste Kettle Machines?

Trusted by pharmaceutical, nutraceutical, cosmetic, and food manufacturers worldwide for reliable heating, uniform agitation, and hygienic processing.

Uniform Heating & Agitation

Precise temperature control combined with anchor or scraper-type agitators ensures uniform heating and lump-free mixing of viscous pastes, creams, gels, and syrups without localized overheating or product burning.

GMP Hygienic Design

Manufactured using food-grade SS304 / SS316 with smooth internal surfaces, sanitary welds, and easy-to-clean geometry to meet stringent GMP and hygiene standards.

Scalable Capacity

Available from laboratory and pilot-scale models to industrial production units, allowing you to scale batch sizes as your process requirements grow.

Built to Last

Robust stainless-steel fabrication and industrial-grade components ensure long service life, stable operation with minimal downtime in continuous production environments.

Energy-Efficient Heating System

Optimized steam or electric heating systems provide efficient heat transfer, reducing energy consumption while maintaining consistent product quality.

Easy Operation & Maintenance

User-friendly control panel, safety interlocks, and accessible components simplify operation, cleaning, and routine maintenance.

Paste Kettle Models and Specifications

Two standard Paste Kettle Machine capacities with customization options for GMP, heating method, and agitation.

cGMP-compliant designs | SS316 contact parts | Custom configurations available

50 L Paste Kettle Machine

Compact and efficient paste kettle designed for R&D, pilot batches, and small-scale production. Ideal for preparing pastes, creams, gels, syrups, and sauces with controlled heating and uniform agitation.

100 L Paste Kettle Machine

Heavy-duty GMP paste kettle engineered for continuous industrial paste processing with consistent heating and reliable agitation.

Machine Specifications

Typical technical specifications for standard paste kettle machines.

| Feature | Paste Kettle - 50 L | Paste Kettle - 100 L |

|---|---|---|

| Working Volume | 50 L | 100 L |

| Product Contact Parts | SS316L | SS316L |

| Non-contact Parts | SS304 | SS304 |

| Motor Power | 1 HP | 1 HP |

| Dimensions | 900×800×1300 mm | 1200×900×1850 mm |

| Weight | 70 kg | 120 kg |

| Input Power | 415 V / 50 Hz / 3-Phase | 415 V / 50 Hz / 3-Phase |

| Warranty | 12 Months | 12 Months |

Specifications may vary depending on material bulk density, product characteristics, and customer-specific customization requirements.

50 L Working Capacity Paste Kettle Machine / Starch Paste Kettle

- Model Type: cGMP / Non-GMP (Optional)

- Working Capacity: 50 L

- Material of Construction (Product Contact Parts): SS316L

- Non-Contact Parts: SS304 or Mild Steel cladded with SS304

- Heating Method: Jacketed vessel with steam or electric heating

- Temperature Range: 40°C to 100°C

- Temperature Control: Digital temperature controller with PID control

- Discharge Mechanism: Manual tilting kettle with handwheel arrangement

- Cleaning System: CIP (Clean-In-Place) compatible design

- Safety Features: Pressure relief valve for safe operation

- Power Supply: 415 V / 50 Hz / 3-Phase

- Motor Power: 1 HP

- Gear Box: Reduction gearbox for controlled agitator speed

- Control Panel: Centralized control panel for operation and monitoring

- Compliance: Designed as per Good Manufacturing Practices (GMP)

100 L Working Capacity Paste Kettle Machine / Starch Paste Kettle

- Model Type: cGMP / Non-GMP (Optional)

- Working Capacity: 100 L

- Material of Construction (Product Contact Parts): SS316L

- Non-Contact Parts: SS304 or Mild Steel cladded with SS304

- Heating Method: Jacketed vessel with steam or electric heating

- Temperature Range: 40°C to 100°C

- Temperature Control: Digital temperature controller with PID control

- Discharge Mechanism: Manual tilting kettle with handwheel arrangement

- Cleaning System: CIP (Clean-In-Place) compatible design

- Safety Features: Pressure relief valve for safe operation

- Power Supply: 415 V / 50 Hz / 3-Phase

- Motor Power: 1 HP

- Gear Box: Reduction gearbox for controlled agitator speed

- Control Panel: Centralized control panel for operation and monitoring

- Compliance: Designed as per Good Manufacturing Practices (GMP)

Paste kettle Machine – Frequently Asked Questions (FAQ)

What is the function of a Paste Kettle Machine?

What are the types of Paste Kettle Machines available?

What is paste in pharmaceutical applications?

What is the working principle of a Paste Kettle Machine?

What materials are used to construct a Paste Kettle Machine?

What type of agitator is used in a Paste Kettle Machine?

How is the paste discharged from the kettle?

Can the Paste Kettle Machine handle high-viscosity materials?

Can the Paste Kettle Machine be customized?

What safety features are provided in a Paste Kettle Machine?

Do you provide installation and after-sales support?

Paste Kettle – Working & Trial Videos

Paste kettle working principle

The working principle of a Paste Kettle Machine is as follows:

Loading of Ingredients: The required ingredients, such as starch and water, are loaded into the kettle. The hemispherical vessel design ensures uniform heat distribution and efficient mixing.

Heating Process: Steam or thermal fluid circulates through the jacketed vessel, heating the product uniformly. This controlled heating process facilitates proper gelatinization and formation of a smooth paste.

Agitation & Mixing: An anchor-type or scraper-type agitator rotates within the kettle to mix the contents thoroughly, ensuring a homogeneous and lump-free product.

Temperature Control: The temperature is precisely regulated using a digital temperature controller to maintain the desired viscosity, texture, and product quality.

Discharge Mechanism: Once the paste reaches the required consistency, the kettle is tilted using a manual handwheel mechanism, allowing clean and controlled discharge of the product.

Cooling & Cleaning: After discharge, the kettle is allowed to cool and is cleaned as per hygiene and GMP guidelines. CIP-compatible designs enable efficient and thorough cleaning.

This working principle ensures consistent production of high-quality pastes, making the Paste Kettle Machine an essential piece of equipment in pharmaceutical, food, cosmetic, and starch processing industries.

Paste kettle machine in pharmaceutical industry

A Paste Kettle Machine, also known as a starch paste kettle or tilting paste kettle, is widely used in pharmaceutical manufacturing for the preparation of ointments, creams, gels, and paste-based formulations. The machine is designed to ensure uniform heating, controlled mixing, and hygienic processing in compliance with cGMP standards.

- Design & Construction: The hemispherical, jacketed vessel ensures efficient heat transfer and uniform temperature distribution. Steam or electric heating enables controlled processing, while the robust stainless-steel construction supports long service life and easy cleaning.

- Functionality: The Paste Kettle Machine performs simultaneous heating and agitation, allowing ingredients to be processed into a smooth, homogeneous paste. This ensures batch-to-batch consistency and uniform product quality.

- Operation: Ingredients are loaded into the kettle and heated to the required temperature. An anchor-type or scraper-type agitator continuously mixes the formulation to maintain homogeneity. Once the desired consistency is achieved, the product is discharged through a controlled manual tilting mechanism.

- Materials & Compliance: Product contact parts are manufactured using SS316 / SS316L stainless steel, while the overall design complies with current Good Manufacturing Practices (cGMP), ensuring hygiene, safety, and regulatory acceptance.

- Pharmaceutical Applications: Paste Kettle Machines are used for manufacturing Ointments, Medicated creams, Gels, Starch pastes, Semi-solid pharmaceutical formulations

paste kettle machine – Machine Video & Product Catalogue

KEY FEATURES OF PASTE KETTLE MACHINE

Uniform Heating with Jacketed Vessel: Steam or electric heating through the jacket ensures even temperature distribution and prevents localized overheating or product burning.

Efficient Agitation for Viscous Materials: Anchor-type or scraper-type agitators provide thorough, lump-free mixing of high-viscosity materials such as starch paste, creams, gels, and ointments.

cGMP-Compliant Hygienic Design: Manufactured using SS316 / SS316L product contact parts with smooth internal surfaces and sanitary construction for contamination-free processing.

Precise Temperature Control: Digital temperature controller with PID control ensures accurate heating and consistent product quality across batches.

Robust & Industrial-Grade Construction: Heavy-duty stainless-steel fabrication ensures long service life, stable operation, and minimal maintenance.

Easy Discharge & Cleaning: Manual tilting mechanism with handwheel allows clean and controlled discharge, while CIP-compatible design simplifies cleaning and maintenance.

Wide Application Range: Suitable for pharmaceutical, nutraceutical, food, cosmetic, and chemical paste processing applications.

paste kettle machine diagram

As above figure reflect the kettle diagram and below are the list of kettle parts.

Paste Kettle Body: To start with, you load ingredients into the main container.

Agitator: The agitator, generally an anchor-type impeller, then mixes the ingredients thoroughly.

Jacketed Design: Steam or thermal fluid next circulates through the outer shell in order to heat the contents.

Temperature Controller: The temperature controller subsequently monitors and regulates the heat inside the kettle.

Discharge Valve: You use the discharge valve at the bottom or side afterwards to remove the paste.

Tilting Mechanism: You additionally tilt the kettle using a handle or handwheel for easy discharging.

Motor: The motor therefore powers the agitator so as to ensure thorough mixing.

Reduction Gear Box: The reduction gear box likewise regulates the speed and torque of the agitator.

Butterfly Valve: The butterfly valve meanwhile controls the flow of ingredients or paste during processing.

Heater: The heater furthermore provides additional heating if required.

Cooling System: You use the cooling system to cool down the kettle once processing is complete.

Cleaning Ports: The cleaning ports thereafter allow for easy access during the cleaning process.

Control Panel: The control panel finally acts as the central interface for operating and monitoring the kettle functions.

I hope this helps you understand the parts of a paste making kettle machine! If you have any more questions or need further details, feel free to contact us.