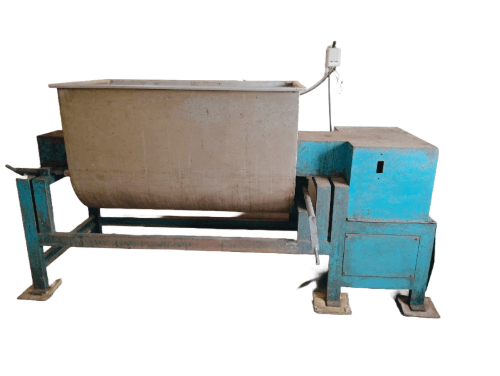

TOBACCO MIXING MACHINE

TOBACCO MIXING MACHINE : Unleashing Efficiency in Powder Mixing

A tobacco mixing machine efficiently blends and homogenizes tobacco products. Consequently, it handles large volumes, ensuring consistent quality and uniformity. You can adjust the variable speed control to achieve the desired blend and consistency. Additionally, tobacco mixing machine features interchangeable blades and customizable discharge options. Moreover, its stainless steel construction ensures durability and easy maintenance. Furthermore, this versatility makes it essential in the tobacco industry for blending, casing, flavoring, granulating, and homogenizing tobacco products. Ultimately, the machine supports efficient and consistent production.

We offer many models in this category, available in 25, 50, 100, and 200 KG per batch capacity.

PARTS of tobacco MIXING machine

PARTS OF TOBACCO MIXING MACHINE AS UNDER

Hopper: Tobacco mixing machine operator initially load the raw tobacco into the hopper. Subsequently, the feeder takes over.

Feeder: The feeder then controls the flow of tobacco from the hopper into the mixing chamber. As a result, it ensures a steady supply.

Mixing Chamber: This chamber of tobacco mixing machine performs the actual blending and homogenization of tobacco. Moreover, it maintains the uniformity of the mix.

Blades: Interchangeable blades cut, shred, or granulate the tobacco to achieve the desired consistency. Furthermore, you can adjust or replace them based on the processing needs.

Variable Speed Control: You can adjust the mixing speed to achieve the precise blend and consistency required for different products. Hence, it provides control over the process.

Discharge Mechanism: Customizable discharge options streamline workflow and enhance operational efficiency. Therefore, it facilitates easy removal of the processed tobacco.

Control Panel: Operators use the control panel to control and monitor the machine’s operations. Additionally, it offers intuitive controls for ease of use.

Stainless Steel Construction: This durable, corrosion-resistant construction ensures ease of maintenance. Thus, it prolongs the machine’s lifespan.

Conveyor System: The conveyor system transports processed tobacco to the next production stage. Consequently, it integrates smoothly into the production line.

Power Supply: The power supply provides the necessary power for efficient machine operation. In essence, it keeps the machine running smoothly.

WHY CHOOSE OUR TOBACCO MIXING MACHINE ?

WHY CHOOSE OUR TOBACCO MIXING MACHINE ?

High Capacity Processing: The machine efficiently handles large volumes of tobacco, significantly boosting production throughput. Consequently, you can meet high-demand schedules with ease.

Variable Speed Control: You can adjust the speed to achieve the desired blend and consistency for different products. Moreover, this feature allows precise control over the mixing process. Therefore, you achieve the exact quality required.

Stainless Steel Construction: This design of tobacco mixing machine ensures durability, ease of maintenance, and resistance to corrosion. Furthermore, it maintains high hygiene standards, thus extending the machine’s lifespan.

Interchangeable Blades: Operators can easily replace or adjust the blades to suit different processing needs, such as blending, shredding, or granulating. Therefore, it offers great versatility in operations. Additionally, this adaptability ensures efficiency.

Customizable Discharge Options: You can streamline workflow with bottom or side discharge options, enhancing operational efficiency. As a result, it fits seamlessly into various production setups. Hence, it contributes to better productivity.

User-Friendly Control Panel: Operators use intuitive controls to monitor and manage the machine’s operations with ease. In addition, this feature of tobacco mixing machine reduces the learning curve and operational errors. Consequently, it improves overall operational efficiency.

Hygienic Design: The machine’s components are easy to clean, reducing contamination risks and maintaining high hygiene standards. Thus, it ensures the safety and quality of the tobacco products. Subsequently, you can meet stringent industry regulations.

Efficient Power Supply: The power supply ensures the machine operates smoothly and efficiently, contributing to overall productivity. Meanwhile, it helps in reducing operational costs. Therefore, it enhances the machine’s reliability.

Robust Mixing Chamber: The chamber provides thorough blending and homogenization, ensuring a uniform mix. Ultimately, this leads to consistent product quality. Moreover, it handles a variety of tobacco types and processing needs.

Applications

Our Tobacco Mixing Machine is ideal for:

Blending

Casing

Flavoring

Granulating

Homogenizing

Moisturizing

Mixing Additives

Batch Processing