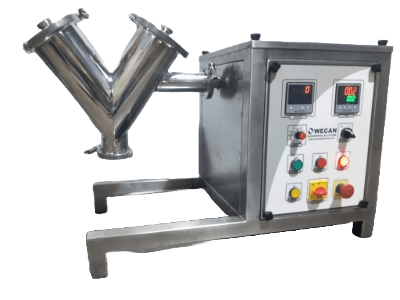

TWIN SHELL BLENDER

TWIN SHELL Blender - REVOLUTIONIZE YOUR MIXING PROCESS WITH WECAN ENGINEERING SOLUTIONS, A LEADING MACHINE MANUFACTURER IN INDIA

Twin Shell Blender Machine manufactured by Wecan Engineering Solutions meets your specific needs, ensuring efficient and consistent blending of powders and granules. Wecan Engineering Solutions is a leading manufacturer of twin shell blender machine in India. Discover the ins and outs of this versatile piece of equipment, widely used in various industries. Learn about its unique V-shaped design, how it operates on a diffusion mechanism, and the best practices for achieving optimal blending results. Whether you’re in food processing, pharmaceuticals, or any other industry requiring precise mixing, this video will guide you through the setup, operation, and maintenance of a Twin Shell Blender.

As a leading manufacturer of Twin shell blender machine, we offer a variety of models in this category. Specifically, we provide options ranging from 5 cubic feet to 200 cubic feet gross volume.

SPECIFICATIONS OF TWIN SHELL BLENDER

Model: Twin Shell Blender Machine

Capacity: Available in various sizes, ranging from 5 cubic feet to 200 cubic feet. This flexibility ensures it meets different production needs.

Material: Constructed with high-quality stainless steel (SS304/SS316 or SS316L) for contact parts. This choice of material guarantees durability and compliance with hygiene standards.

Design: Featuring a V-shaped mixing chamber, made of two hollow cylindrical shells joined at an angle of 75° to 90°. This design promotes efficient mixing.

Mixing Time: Typically, it takes between 10 to 15 minutes, depending on the material being blended. Consequently, this ensures quick and efficient blending.

Speed: Operates at a medium speed to ensure efficient blending without causing excessive dusting. This makes it ideal for delicate materials.

Loading/Unloading: Equipped with two openings on top of the V for easy loading and unloading of materials. Thus, this design simplifies the operation process.

Safety Features: Includes interlock mechanisms and emergency stop buttons for safe operation. Thus, it guarantees a safe working environment.

Maintenance: Designed for minimal maintenance with easily accessible parts. Therefore, cleaning and upkeep are straightforward and hassle-free.

Applications: Suitable for pharmaceuticals, food processing, chemicals, construction, and other industries requiring dry bulk solids mixing. This versatility makes it a valuable addition to any production line.

| Sr no | Specifications | Details |

|---|---|---|

| 1 | Capacity | 10 kg, 25 kg, 50 kg, 100 kg, 200 kg, 300 kg, 500 kg, 1000 kg, 2000 kg, 5000 kg |

| 2 | Gross Volume | 35 L, 80 L, 150 L, 300 L, 450 L, 600 L, 800 L, 900 L |

| 3 | Motor Power | 0.5 HP, 1 HP, 2 HP, 3 HP, 5 HP, 7.5 HP, 10 HP, up to 50 HP |

| 4 | Gear Box | Elecon, Redicon, CPEC, Shanthi make |

| 5 | Material | Stainless Steel (SS304, SS316) |

| 6 | Construction | Stainless Steel frames |

| 7 | Butterfly Valve | Equipped for efficient discharge |

| 8 | Safety Features | Safety guard, interlock systems, overload protection |

| 9 | Discharge Height | 300 mm, 450 mm |

| 10 | Additional Features | Dust-free bin charging system, flame-proof electricals, PLC + HMI base systems, slant design, manual rotating facility with hand wheel, polished interior and exterior surfaces, mirror polished fixed buffers inside the cone, three-phase indication, D.O.L. tarter, digital timer, Amp Meter |

key FEATURE

GMP Compliant Design: Our machine strictly adheres to Good Manufacturing Practices (GMP) guidelines, ensuring your production process remains safe and compliant with regulatory requirements.

- Advanced Sensor Technology: With precision engineering, our Twin Shell Blender Machine monitors and controls temperature, spray rate, and coating thickness with pinpoint accuracy. Consequently, this guarantees a uniform and consistent coating every time.

- Versatile Capabilities: Whether you work with various tablet shapes, sizes, or coating formulations, our machine adapts seamlessly to your needs. Hence, It handles a wide range of batch sizes, making it suitable for both small and large-scale productions.

User-Friendly Operation: In the dynamic world of pharmaceutical and chemical manufacturing, achieving uniform mixing is crucial. This Machine meets your specific needs, ensuring efficient and consistent blending of powders and granules. Furthermore, the intuitive interface and easy maintenance features make our Machine incredibly user-friendly. Consequently, routine cleaning and upkeep are straightforward, minimizing downtime and maximizing productivity. Discover the ins and outs of this versatile piece of equipment, widely used in various industries. Learn about its unique V-shaped design, how it operates on a diffusion mechanism, and the best practices for achieving optimal blending results.

Robust After-Sales Support: Our commitment to your success extends beyond the purchase. Further more, We provide professional after-service support to ensure your machine operates smoothly and efficiently.

BENEFIT OF TWIN SHELL BLENDER

- Enhanced Protection: Our Twin Shell Blender Machine provides a protective barrier that shields your products from environmental factors such as air, light, and humidity. Consequently, this extends the shelf life and stability of your drugs.

- Improved Patient Experience: By masking unpleasant tastes and odors, our machine makes tablets more palatable and easier to swallow. Thus, this enhances patient compliance.

Aesthetic Appeal: Achieve a polished, professional look with a smooth and uniformly coated surface. Moreover, our machine ensures that your tablets stand out on the shelf with attractive and consistent coloring.

Anti-Counterfeiting Measures: Incorporate tracer compounds in the coating material to safeguard your products against counterfeiting. Thus, ensuring the integrity and trustworthiness of your brand.

Operational Efficiency: Our Machine is designed for efficiency. It allows for the containment of highly potent compounds within the tablet core, minimizing exposure to personnel, thereby enhancing safety in your production facility.

Applications

Our Twin Shell Blender Machine is ideal for:

- Pharmaceuticals

- Nutraceuticals

- Herbal supplements

- Chemical or cosmetics

PRICE OF TWIN SHELL BLENDER IN INDIA

A Twin Shell Blender, also known as twin shell dry blender, is a versatile piece of equipment widely used in various industries such as pharmaceuticals, chemicals, food, and cosmetics. Its primary function is to mix powders and granules uniformly. The price of this machine can vary based on several factors:

Capacity: The capacity of a this machine can range from a few liters to several hundred liters. Larger capacities usually come at a higher cost.

Material: Blenders made from high-quality stainless steel are more expensive than those made from other materials, due to their durability and ease of cleaning.

Features: Additional features such as intensifier bars, variable speed control, and explosion-proof motors can increase the price of the blender.

Here are some example price ranges based on these factors:

Small Capacity (up to 5 liters): ₹50,000 – ₹1,00,000

Medium Capacity (5 to 50 liters): ₹1,00,000 – ₹5,00,000

Large Capacity (50 liters and above): ₹5,00,000 and above

Please note that these prices are indicative and can vary based on the specific requirements and customization options. For an accurate quote, it is recommended to contact us directly.