TYPES OF BLENDER IN PHARMA

TYPES OF BLENDER IN PHARMA ARE OCTAGONAL BLENDER, V-SHAPE BLENDER / v-CONE BLENDER / TWIN SHELL BLENDER, DOUBLE CONE BLENDER, RIBBON BLENDER, AND TUMBLER BLENDER.

Different types of blender in pharma play a crucial role in the pharmaceutical industry. They mix active pharmaceutical ingredients (APIs) and excipients thoroughly and uniformly. This uniformity ensures consistent dosage and maintains the integrity and efficacy of medications. Moreover, during the granulation process, blenders form granules by mixing powders with binder solutions, enhancing the flow properties of the powder mixture, which is vital for tablet compression.

Additionally, blenders achieve a homogeneous mixture of different components, ensuring uniform distribution of fine particles and stability of the final product. In addition, they mix coating solutions applied to tablets, improving taste and protecting active ingredients. Furthermore, in powder blending, blenders mix multiple powders or powders with liquid binders to ensure consistency. Moreover, they help create formulations with enhanced dissolution rates, improving the bioavailability of drugs. Overall, blenders are indispensable in producing safe and effective medications by ensuring precise mixing and uniform distribution of ingredients.

OCTAGONAL types of BLENDER in pharma

- This types of blender in pharma is called Octagonal Blender. Wecan Engineering Solutions plays a crucial role in the homogeneous mixing of dry powders and granules. Firstly, its unique octagonal shape creates an efficient tumbling action that evenly distributes materials. Moreover, constructed from high-quality stainless steel, this blender ensures durability and ease of cleaning. Operating at low to medium speeds, it offers various capacities ranging from a few hundred to several thousand liters, making it suitable for different applications. Additionally, equipped with interlocking systems and safety switches, it guarantees safe operation.

- Industries widely use the Octagonal Blender from Wecan Engineering Solutions for its versatility and effectiveness. In pharmaceuticals, it mixes active ingredients and excipients, while in the food industry, it blends spices and seasonings. The chemical industry relies on it for mixing fine powders and granules. Furthermore, the blender’s efficient mixing capability ensures uniform distribution, and its comprehensive safety features and user-friendly design make it reliable. Overall, this indispensable tool from Wecan Engineering Solutions provides consistent, high-quality results across various industrial applications. Visit our you tube channel for Octagonal Blender Video.

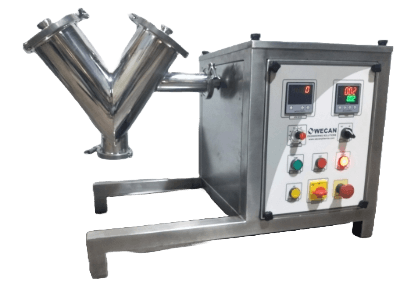

V-SHAPE BLENDER / v-CONE BLENDER / TWIN SHELL types of BLENDER in pharma

- This types of blender in pharma is called V-Shape Blender or V-Cone Blender or Twin Shell Blender. Wecan Engineering Solutions is a versatile and efficient machine designed for the uniform mixing of dry powders and granules. Firstly, its V-shaped design creates a unique tumbling action that ensures thorough and homogeneous mixing of materials. Additionally, this blender features high-quality stainless steel construction, offering both durability and ease of cleaning. The V Cone Blender operates at low to medium speeds, making it suitable for a variety of applications, with capacities ranging from a few hundred to several thousand liters. Moreover, safety is a top priority, as the blender is equipped with interlocking systems and safety switches to ensure safe operation.

- Industries widely utilize the V Cone Blender from Wecan Engineering Solutions due to its versatility and effectiveness. In the pharmaceutical industry, it excels at mixing active ingredients and excipients, ensuring consistent and accurate dosages. In the food industry, the blender efficiently blends spices, seasonings, and other dry ingredients, maintaining product quality and uniformity. The chemical industry also benefits from the V Cone Blender for its ability to mix fine powders and granules with precision. Furthermore, the blender’s efficient mixing capability, comprehensive safety features, and user-friendly design make it a reliable choice for various industrial applications. Overall, the V Cone Blender from Wecan Engineering Solutions delivers consistent, high-quality results, making it an indispensable tool for achieving optimal blending performance.Visit our you tube channel for V Cone Blender Video.

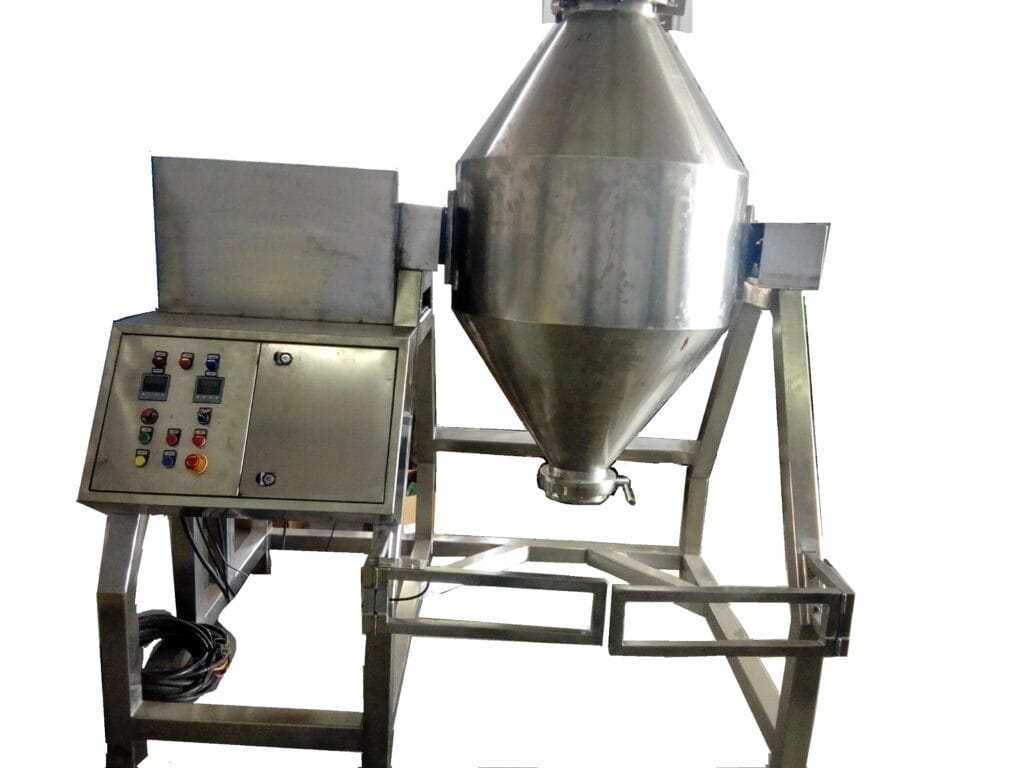

DOUBLE CONE BLENDER

- This types of blender is called Double Cone Blender from Wecan Engineering Solutions is an advanced and versatile mixing machine designed for the efficient blending of dry powders and granules. Firstly, its double-cone design creates a unique tumbling action that ensures thorough and homogeneous mixing of materials. Additionally, this blender features high-quality stainless steel construction, providing durability and ease of cleaning. The Double Cone Blender operates at low to medium speeds, making it suitable for a variety of applications, with capacities ranging from a few hundred to several thousand liters. Moreover, it comes equipped with interlocking systems and safety switches to ensure safe and reliable operation.

- Industries extensively use the Double Cone Blender from Wecan Engineering Solutions due to its versatility and effectiveness. In the pharmaceutical industry, it excels at mixing active ingredients and excipients, ensuring consistent and accurate dosages in the final product. In the food industry, the blender efficiently blends spices, seasonings, and other dry ingredients, maintaining product quality and uniformity. The chemical industry also benefits from the Double Cone Blender for its ability to mix fine powders and granules with precision. Furthermore, the blender’s efficient mixing capability, comprehensive safety features, and user-friendly design make it a reliable choice for various industrial applications. Overall, the Double Cone Blender from Wecan Engineering Solutions delivers consistent, high-quality results, making it an indispensable tool for achieving optimal blending performance.Visit our you tube channel for Double Cone Blender Video.

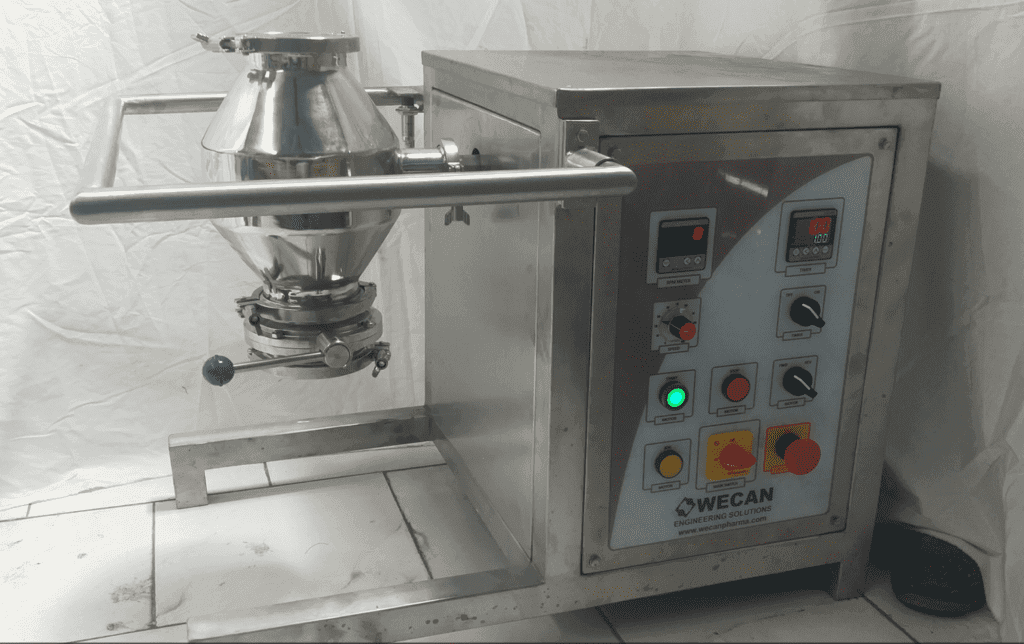

3d TUMBLER BLENDER OR HAND OPERATED MANUAL TUMBLER BLENDER

- This types of blender in phara is called Tumbler mixer. Wecan Engineering Solutions is a versatile mixing machine designed to efficiently blend dry powders and granules. Firstly, its rotating action ensures thorough and uniform mixing, resulting in a homogeneous mixture every time. Additionally, its high-quality stainless steel construction ensures durability and easy cleaning, making it ideal for industrial use. Operating at low to medium speeds, this blender caters to a variety of applications, with capacities ranging from a few hundred to several thousand liters. Moreover, it comes equipped with essential safety features, including interlocking systems and safety switches, to guarantee secure operation.

- The hand-operated manual tumbler mixer is a practical solution for mixing small quantities of dry powders and granules. Firstly, it requires manual effort to rotate the tumbler, ensuring thorough blending of materials. Additionally, it is typically constructed from stainless steel, providing durability and ease of cleaning. Operating manually, this blender is perfect for small-scale applications or laboratory settings where precise control over the blending process is essential. Moreover, its compact and portable design makes it easy to use in various environments, offering flexibility and convenience.Visit our you tube channel for Tumbler Mixer Video.