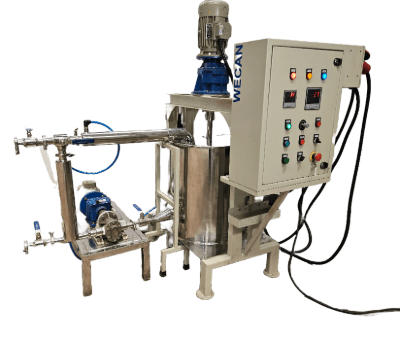

CHOCOLATE BALL MILL MACHINE

CHOCOLATE BALL MILL MACHINE MANUFACTURER - WECAN ENGINEERING SOLUTIONS.

A chocolate ball mill machine plays a crucial role in refining the texture and enhancing the flavor of chocolate. Wecan Engineering Solutions is a leading chocolate ball mill machine in India. The machine features a steel cylinder filled with numerous small steel balls. These balls rotate to crush and mix the chocolate ingredients, such as cocoa solids, milk powder, and sugar. Consequently, this grinding action reduces the particle size of the ingredients, resulting in a smoother and more homogeneous chocolate mass. Furthermore, the machine includes a motor to control the rotation, a temperature controller to maintain ideal processing conditions, and a removable lid for easy observation and cleaning. With consistent and efficient grinding and mixing, the chocolate ball mill machine significantly improves the texture and appearance of the chocolate while intensifying its flavor profile. Therefore, it becomes an indispensable tool for both small-scale and large-scale chocolate production.

In addition, Wecan Engineering Solutions manufactures high-quality chocolate ball mill machines known for their durability, efficiency, and precision. Their machines cater to the diverse needs of chocolate producers, ensuring optimal performance and exceptional results in chocolate manufacturing. By committing to innovation and customer satisfaction, Wecan Engineering Solutions leads the industry with their cutting-edge technology.

BALL MILL MACHINE PRICE IN INDIA

Wecan Engineering Solutions offers competitive prices for chocolate ball mill machines in India.

Laboratory-scale machines with capacities of 5kg to 20kg per batch cost approximately ₹2,45,000 to ₹2,80,000.

Small chocolate ball mill machine, designed for entry-level industrial production with capacities of 150kg to 500kg per batch, range from ₹2,80,000 to ₹3,50,000.

Medium-scale machines, which produce outputs of 100-300kg per hour, are priced around ₹3,50,000 to ₹4,50,000.

For large-scale production, high-capacity machines that process up to 1500kg per hour cost ₹16,50,000 or more.

Chocolate ball mill machine price in India may vary based on specific requirements and configurations.

For precise pricing, contact Wecan Engineering Solutions directly

QUALITY OF OUR Machines

Wecan Engineering Solutions offers superior chocolate ball mill machine for several reasons:

Quality Construction: We use high-grade materials, ensuring durability and long-lasting performance.

Efficiency: Our chocolate ball mill machine for chocolate optimize the grinding and mixing process, saving time and energy while consistently delivering excellent results.

Precision: Advanced technology precisely controls the grinding process, resulting in a smooth, homogeneous chocolate mass with a rich flavor profile.

Versatility: We offer machines in various sizes to meet the needs of small-scale, medium-scale, and large-scale chocolate production.

Customer Support: Our dedicated team provides exceptional customer service and technical support, helping you get the most out of your machine.

Innovation: We continuously improve our designs based on customer feedback and industry trends, keeping our machines at the forefront of chocolate manufacturing technology.

Therefore, choosing Wecan Engineering Solutions means you invest in reliability, efficiency, and quality for your chocolate production needs.

CHOCOLATE BALL MILL MACHINE FOR INDUSTRIAL USE

Chocolate ball mill machine, provided by Wecan Engineering Solutions, efficiently create a smooth and homogeneous chocolate mass. Firstly, our machines feature a steel cylinder with small steel balls that grind and mix chocolate ingredients like cocoa solids, milk powder, and sugar. This grinding action reduces particle size, resulting in a fine, consistent texture. Moreover, our advanced temperature control systems maintain ideal processing conditions to ensure high-quality output. Additionally, our machines integrate seamlessly with other equipment, streamlining the production process for large-scale operations. Therefore, Wecan Engineering Solutions designs reliable and efficient chocolate ball mill machines tailored for industrial needs.

SMALL CHOCOLATE BALL MILL MACHINE FOR HOME USE

Small chocolate ball mill machines from Wecan Engineering Solutions are perfect for home use, offering the ability to create smooth and delicious chocolate right in your kitchen. These compact machines feature a steel cylinder filled with small steel balls that grind and mix chocolate ingredients like cocoa solids, milk powder, and sugar. The grinding action reduces the particle size, resulting in a fine, consistent texture. Many models include temperature control systems to maintain ideal processing conditions and ensure high-quality output. Additionally, they often stop operation when the lid is opened to protect users. Small chocolate ball mill machines from Wecan Engineering Solutions are ideal for hobbyists and home chocolatiers who want to experiment with chocolate making.