3D Tumbler mixer machine | High-Precision | GMP Model

Trusted by pharmaceutical, chemical, cosmetic, battery, and specialty material manufacturers worldwide

High-precision 3D tumbler mixers designed with three-dimensional movement to achieve consistent and homogeneous blending in GMP applications.

- Capacity: Lab models to 100 kg industrial scale

- Unique 3 Dimentional rotation for uniform mixing

- SS316 / SS304 Food-grade stainless steel

- Precise speed control for uniform mixing

- Safety inter-lock & digital timer

- Suitable for pharmaceutical, chemical, food, and specialty material processing

Ready to scale your powder mixing process?

Get a personalized quote for the 3D Tumbler Mixer Machine that fits your process requirements.

Our team responds within 24 hours with technical recommendations and pricing.

Choose your 3D tumbler mixer model

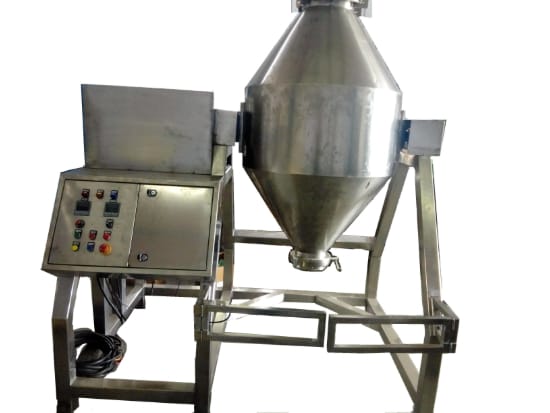

Manual 3D Tumbler Mixer Machiner

Compact lab model for R&D and small trial batches. Ideal for product development and sampling application

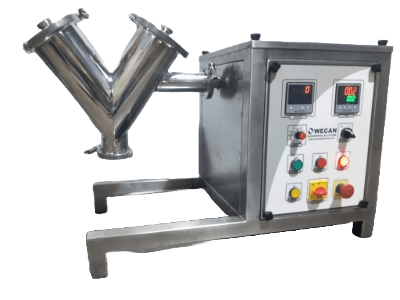

Automatic 3D Tumbler Mixer Machine

Compact lab model for R&D and small trial batches, offering precise control of speed, time, and safety parameters.

Why choose Our 3D tumbler mixer Machines?

Trusted by pharmaceutical, abrasive, battery, cement, ceramic, cosmetic, diamond tools, explosives, fireworks, metal powder, photochemistry, plastic, and polymer industries worldwide for over 10 years as a leading 3D tumbler mixer manufacturer.

Uniform 3-Dimensional Mixing

The unique 3D tumbling motion ensures complete axial, radial, and translational movement of the material, delivering highly homogeneous mixing without dead zones or segregation.

Gentle & Segregation-Free Process

Designed for fragile, granular, and powder blends, the low-shear tumbling action preserves particle integrity and prevents size or density segregation.

Ideal for Pharmaceutical & Precision Blends

Perfect for APIs, excipients, chemicals, metal powders, and specialty materials where high homogeneity is required without aggressive mechanical agitation.

Built to Last

Robust stainless steel construction, a precision-balanced drive system and industrial-duty components ensure reliable operation, long service life, and consistent performance batch after batch.

GMP-Compliant Hygienic Design

Manufactured with SS304 / SS316 contact parts, smooth internal surfaces, and crevice-free construction for easy cleaning and full compliance with GMP standards.

Energy-Efficient & Low Maintenance

Optimized drive system with minimal power consumption, fewer moving parts, and robust construction ensures long service life with minimal maintenance and reduced downtime.

3D tumbler mixer machine Models and Specifications

Two specialized models designed to meet three-dimentional mixing process.

cGMP-compliant designs | SS316 contact parts | Custom configurations available

Manual 3D tumbler mixer machine

Best suited for small trial batches with manual operation

Automatic 3D tumbler mixer machine

Best suited for small trial batches with automatic operation

Machine Specifications – 3D Tumbler Mixer Machine

| Sr. no. | Container / Bin Volume (L) | Working capacity (kg) | Container /Bin Material | Body and Other parts Material | Drive Type |

|---|---|---|---|---|---|

| 1 | 0.5 | 0.35 | SS316 | SS304 | Manual (Hand Operated) |

| 2 | 1 | 0.7 | SS316 | SS304 | Manual (Hand Operated) |

| Sr. no. | Container / Bin Volume (L) | Working capacity (kg) | Container /Bin Material | Body and Other parts Material | Main Motor Power in (HP) | Power supply requirement | Approx. Power Consumption (kW) |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 0.35 | SS316 | SS304 | 0.25 | Single Phase | 0.2 |

| 2 | 2 | 0.7 | SS316 | SS304 | 0.25 | Single Phase | 0.2 |

| 3 | 3 | 1 | SS316 | SS304 | 0.5 | Single Phase | 0.4 |

| 4 | 5 | 1.7 | SS316 | SS304 | 0.5 | Single Phase | 0.4 |

| 5 | 10 | 3.5 | SS316 | SS304 | 0.5 | Single Phase | 0.4 |

| 6 | 15 | 5 | SS316 | SS304 | 0.5 | Single Phase | 0.4 |

Specifications are indicative and subject to change depending on material characteristics, process requirements, and customization options.

Manual 3D tumbler mixer machine

- Constructed from high-grade Stainless Steel SS 304 / SS 316, built to suitable dimensions

- Employs true 3-dimensional mixing motion for uniform blending

- Detachable mixing bin for easy loading, unloading, and cleaning

- Mounted on a robust ISMC section stand with necessary protective covers

Automatic 3D tumbler mixer machine

- Constructed from high-grade Stainless Steel SS 304 / SS 316, built to suitable dimensions

- Employs true 3-dimensional mixing motion for uniform blending

- Detachable mixing bin for easy loading, unloading, and cleaning

- Bin RPM controlled through a Variable Frequency Drive (VFD) for precise speed regulation

- Driven by a suitable single-phase or three-phase motor, coupled with a worm gearbox

- Mounted on a robust ISMC section stand with protective covers for motor, and gearbox

3D Tumbler mixer machine – Frequently Asked Questions (FAQ)

What materials can I mix with the 3D Tumbler Mixer?

Is the mixer easy to clean and maintain?

What is the warranty on this mixer?

Can I Use a 3D Tumbler Mixer for Pharmaceutical Applications?

How Long Does It Take to Mix Materials in a 3D Tumbler Mixer?

What Utilities Are Required to Operate the Machine?

Do You Provide Installation Support and Documentation?

Can the Tumbler Mixer Be Customized for Specific Needs?

What Capacity Range Is Available?

Is the machine export-ready for overseas supply?

3D Tumbler mixer machine – Working & Trial Videos

3D tumbler mixer machine - working principle

The 3D tumbler mixer operates on a true three-dimensional mixing principle to achieve thorough and uniform blending. The mixing container undergoes simultaneous rotational, translational, and tumbling movements, ensuring complete material circulation without dead zones.

The working principle involves the following motions:

The mixing container rotates around its central axis, continuously turning the material to prevent settling or adhesion to the container walls.

The container moves back and forth horizontally, allowing materials to redistribute evenly throughout the mixing chamber.

The container periodically flips or inverts, creating a gentle tumbling action that forces particles to move in multiple directions, ensuring uniform mixing regardless of particle size, shape, or density.

This combined 3D motion reduces mixing time and improves blending efficiency compared to conventional mixers.

As a result, the 3D tumbler mixer produces a highly homogeneous mixture, making it ideal for applications where uniformity is critical. It is widely used for dry powders, granules, and low-moisture blends in pharmaceutical, food, chemical, and R&D applications.

Tumbler Mixer machine by wecan engineering solutions to revolutionizing your mixing experience.

The 3D tumbler mixer machine from Wecan Engineering Solutions is designed to deliver consistent, efficient, and gentle mixing across laboratory and industrial applications. Its low-shear three-dimensional motion preserves particle integrity while ensuring uniform blending.

Compared to traditional mixers that may leave unmixed material at the bottom, the 3D tumbler mixer ensures complete material integration in every batch. With robust construction, reliable performance, and ease of operation, it is a preferred solution for professionals seeking precision, repeatability, and process reliability.

Automatic 3D tumbler mixer machine – Machine Video & Product Catalogue

- KEY FEATURES OF AUTOMATIC TUMBLER MIXER MACHINE

True three-dimensional mixing motion ensures complete and uniform blending without dead zones.

Low-shear tumbling action preserves particle integrity and prevents segregation.

Highly homogeneous mixture suitable for pharmaceutical, food, chemical, and R&D applications.

Versatile material handling, ideal for powders, granules, and low-moisture blends.

Optimized mixing efficiency reduces batch time while improving consistency.

Precision and repeatability ensure consistent results batch after batch.

Robust GMP-oriented design engineered for reliable operation and long service life.

small manual or hand operated 3D tumbler mixer machine - Machine Video & Product Catalogue

KEY FEATURES OF MANUAL TUMBLER MIXER MACHINE

True three-dimensional mixing motion ensures uniform blending without dead zones.

Gentle tumbling action prevents segregation and preserves particle integrity.

Highly homogeneous mixture suitable for pharmaceutical, food, chemical, and R&D applications.

Ideal for powders, granules, and low-moisture blends in small trial and laboratory batches.

Manual hand-operated mechanism allows precise control without electrical power.

Compact and robust construction designed for reliable operation and long service life.

tumbler mixer machine price in india

Tumbler Mixer Machine Price in India

Wecan Engineering Solutions offers a range of 3D Tumbler Mixer Machines in India, with pricing varying based on model type, capacity, material of construction, and optional features.

Manual / Hand-Operated 3D Tumbler Mixer (Lab Model):

Indicative price starts from ₹65,000, suitable for R&D, sampling, and small trial batches.Automatic 3D Tumbler Mixer Machine:

Indicative price ranges from ₹75,000 to ₹1,90,000, depending on batch capacity, motor power, control features (VFD, timer), and material grade.

Prices are indicative and may vary based on customization, application requirements, and applicable taxes.

tumbler mixer manufacturer in india

Wecan Engineering Solutions is a manufacturer of 3D Tumbler Mixer Machines in India, offering manual and automatic models designed to meet pharmaceutical, chemical, food, and R&D industry requirements.

Our machines are engineered with a focus on uniform mixing, GMP-compliant construction, reliability, and long service life. Custom configurations are available to suit specific process and application needs.

📞 For technical assistance or quotation: +91 97277 94689

📄 To download the product catalogue or request a quote, please use the enquiry form on this page.

Explore alternative powder mixing solutions based on your process requirements.