V CONE BLENDER Machine | High-Precision | GMP Model for Pharmaceutical, neutraceutical & Food Industries

Trusted by pharmaceutical, nutraceutical & food manufacturers for over a decade

Custom-built V cone blender machines engineered for gentle yet efficient tumbling action, ensuring uniform mixing, smooth material flow, and minimal product degradation—ideal for free-flowing powders and granules.

- Capacity: Lab models to 5000 kg industrial scale

- SS316 / SS304 food-grade stainless steel

- Precise speed control for uniform mixing

- Safety inter-lock & digital timer

- Best for Pharma, Nutraceutical & Food industries

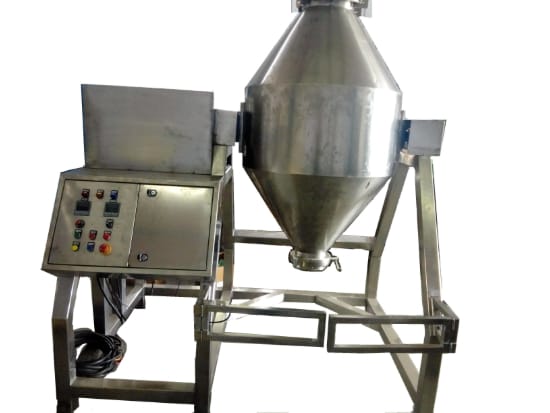

Production scale V Cone Blender Machine

For large batch pharmaceutical & food manufacturing. Capacity up to 5000 kg per batch

Ready to Scale Your Powder Blending Process?

Get a personalized quote for the V Cone Blender model that fits your needs. Our team replies within 24 hours with recommendations and pricing.

Tell us your requirement (model, batch size, material, application)

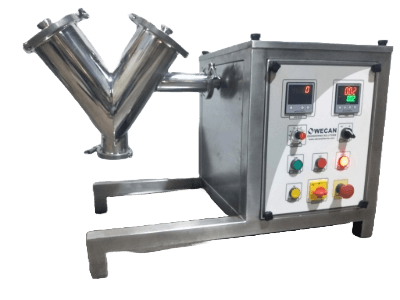

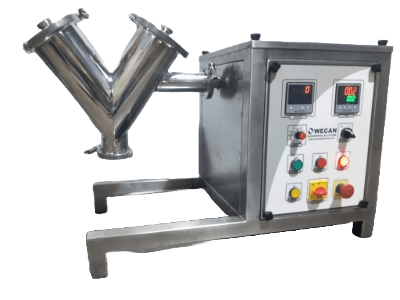

Laboratory Scale V Cone Blender

Compact laboratory model designed for R&D, formulation development, and small trial batches. Ideal for product testing and sampling.

Production Scale V Cone Blender

Heavy-duty industrial V cone blender scalable up to 5000 kg batch capacity. Suitable for pharmaceutical, food, and chemical manufacturing.

Why choose Our V cone Blender Machines?

Trusted by pharmaceutical, nutraceutical, and food manufacturers worldwide for precision, consistency, and performance.

Precision Mixing

Variable bin speed and controlled tumbling motion ensure uniform and repeatable blending of powders and granules.

GMP Hygienic Design

Constructed in food-grade SS 316 / SS 304 with smooth surfaces and easy-to-clean geometry to meet strict GMP requirements.

Scalable Capacity

Available from laboratory-scale R&D models to production units scalable up to 5000 kg per batch.

Built to last

Robust stainless construction and high-quality components deliver long service life and minimal downtime.

Energy Efficient

Optimised motor selection with VFD control reduces power consumption without compromising mixing performance.

Easy Maintenance

Tool-free access panels, modular parts, and quick-disconnect fittings make servicing fast and cost-effective.

V cone Blender Models and Specifications

Four specialized models designed to meet every scale of powder mixing.

cGMP-compliant designs | SS316 contact parts | Custom configurations available

Laboratory Scale V Cone Blender

Available in 2 kg, 5 kg, and 10 kg capacities.

Compact and portable—ideal for R&D, trial batches, and testing.

Standard laboratory models available for online purchase.

100 kg V Cone Blender

GMP-compliant model with a gross volume of 300 L, suitable for 100 kg per batch production.

200 kg V Cone Blender

GMP-compliant model with a gross volume of 600 L, suitable for 200 kg per batch production.

500 kg V Cone Blender

GMP-compliant model with a gross volume of 1500 L, suitable for 500 kg per batch production.

Machine Specifications

Typical technical specifications for standard v cone blender machines.

| Sr. No. | Gross Volume (L) | Working capacity (kg) | Product Contact Parts | Non-Contact Parts | Main Motor Power (HP) | Overall Dimensions (mm) LxWxH | Blending Speed (RPM) | Machine Weight (kg) | Power Supply | Avg. Power Consumption (kWh) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 6 / 15 / 30 | 2 / 5 / 10 | SS316 | SS304 | 1 | 350x600x900 | 3 - 25 | 90 | Single Phase | 0.75 |

| 2 | 300 | 100 | SS316 | SS304 | 5 | 1500x1000x1300 | 3 - 20 | 210 | Three Phase | 3.7 |

| 3 | 600 | 200 | SS316 | SS304 | 7.5 | 1600x1200x1400 | 3 - 15 | 350 | Three Phase | 5.5 |

| 4 | 1500 | 500 | SS316 | SS304 | 15 | 1700x1300x1900 | 3 - 10 | 850 | Three Phase | 11 |

Specifications may vary depending on material bulk density, product characteristics, and customer-specific customization requirements.

Laboratory Scale V Cone Blender

- Model: cGMP and Non-GMP (Optional)

- Batch capacity: 2 kg, 5 kg, and 10 kg

- Container gross volume: 6 L, 15 L, and 30 L

- Product contact parts: SS316L

- Non-contact parts: SS304 or MS cladded with SS304

- Motor: 1 HP, Single Phase

- Safety railing with interlock

- Discharge: TC-ended or Butterfly valve

- Custom configurations available on request

300 L Gross Volume V Cone Blender

- Model: cGMP and Non-GMP (Optional)

- Batch capacity: 100 kg

- Container gross volume: 300 L

- Product contact parts: SS316L

- Non-contact parts: SS304 or MS cladded with SS304

- Motor: 5 HP, Three Phase

- Safety railing with interlock

- Discharge: 6-inch manually operated Butterfly valve

- Custom configurations available on request

600 L Gross Volume V Cone Blender

- Model cGMP and Non-GMP (Optional)

- Batch capacity: 200 kg

- Container gross volume: 600 L

- Product contact parts: SS316L

- Non-contact parts: SS304 or MS cladded with SS304

- Motor: 7.5 HP, Three Phase

- Safety railing with interlock

- Discharge: 6-inch manually operated Butterfly valve

- Custom configurations available on request

1500 L Gross Volume V Cone Blender

- Model cGMP and Non-GMP (Optional)

- Batch capacity: 500 kg

- Container gross volume: 1500 L

- Product contact parts: SS316L

- Non-contact parts: SS304 or MS cladded with SS304

- Motor: 15 HP, Three Phase

- Safety railing with interlock

- Discharge: 10-inch manually operated Butterfly valve

- Custom configurations available on request

V cone Blender Machine – Frequently Asked Questions (FAQ)

How does your V Cone Blender machine work?

What types of materials can be mixed in your V Cone Blender?

What batch sizes are available in your V Cone Blender range?

Are your V Cone Blender machines GMP compliant?

What materials are used for product contact and non-contact parts?

How long does the mixing process take?

What safety features are provided in your V Cone Blender?

What discharge options are available?

Can the V Cone Blender be customized?

V cone Blender machine – Working & Trial Videos

V Cone Blender / Mixer Machine - Engineered by Wecan Engineering Solutions

Our V Cone Blender Machine, also known as a V Blender or V Cone Mixer, is designed for uniform, gentle, and contamination-free mixing of dry powders and granules. Manufactured by Wecan Engineering Solutions, these machines are widely used in pharmaceutical, nutraceutical, food, and chemical industries for both R&D and large-scale production.

The V Cone Blender ensures consistent blend homogeneity, minimal product degradation, and easy cleaning, making it ideal for applications that demand precision and repeatability. Available in laboratory and production-scale models, our machines can be customized to meet specific process and compliance requirements.

Working Principle of V Cone Blender / Mixer

The V Cone Blender operates on a tumbling diffusion mixing principle, where material movement is driven by gravity rather than mechanical agitation.

V-Shaped Vessel Design – The blender consists of two interconnected V-shaped chambers mounted on a horizontal axis.

Gentle Tumbling Action – As the vessel rotates, the material continuously splits and recombines between the two cones, promoting uniform distribution.

Diffusion-Based Mixing – The repeated division and merging of material creates a diffusion effect, resulting in a homogeneous blend without high shear.

Uniform & Consistent Blending – This motion ensures even mixing of powders and granules with minimal segregation.

No Internal Moving Parts – Absence of internal agitators reduces contamination risk and simplifies cleaning and maintenance.

Smooth Internal Surfaces – Polished surfaces prevent material build-up and support GMP-compliant cleaning.

Wide Application Range – Suitable for pharmaceutical powders, nutraceutical blends, food ingredients, cosmetic formulations, and specialty chemicals.

v cone blender price in india

The price of a V Cone Blender Machine in India depends on several factors, including batch capacity, material of construction, GMP compliance, motor specifications, discharge type, and customization requirements.

Indicative price ranges are as follows:

Laboratory Scale V Cone Blender (2–10 kg / 6–30 L)

Prices typically start from ₹2.5 lakh onwards, depending on configuration and compliance level.Production Scale V Cone Blender (100–500 kg / 300–1500 L)

Prices generally start from ₹5 lakh onwards, varying with batch capacity, automation level, and material specifications.Fully Customized Industrial Models

Pricing depends on specific process requirements, optional features, and validation needs.

For accurate and application-specific pricing, it is recommended to request a customized quotation based on your material characteristics, batch size, and regulatory requirements.

V cone blender machine general specifications

| Sr no | Specifications | Details |

|---|---|---|

| 1 | Capacity | 2 kg, 5 kg, 10 kg, 100 kg, 200 kg, 500 kg |

| 2 | Gross Volume | 6 L, 15 L, 30 L, 300 L, 600 L, 1500 L |

| 3 | Motor Power | 1 HP, 5 HP, 7.5 HP, 15 HP |

| 4 | Gear Box | Heavy-duty gearbox – reputed make |

| 5 | Product contact parts | SS316L |

| 6 | Non-Contact Parts | SS304 or MS cladded with SS304 |

| 7 | Discharge Type | TC-ended outlet or butterfly valve |

| 8 | Safety Features | Safety railing with interlock, emergency stop, overload protection |

| 9 | Control Panel | Push-button control panel or PLC + HMI (optional) |

| 10 | Additional Features | Polished internal surfaces, digital timer, VFD speed control, manual rotating facility, GMP-compliant design |

Production Scale v cone Blender – Machine Video & Product Catalogue

Our Production Scale V Cone Blender is designed for uniform, gentle, and contamination-free mixing of dry powders and granules in pharmaceutical, nutraceutical, food, and chemical industries. Manufactured using high-quality stainless steel, the V-shaped vessel enables tumbling diffusion mixing, ensuring consistent blend homogeneity without high shear or product degradation.

These machines are available in production capacities ranging from 100 kg to 500 kg per batch, with GMP-compliant construction, safety interlocks, and easy-to-clean surfaces. Variable speed control and robust mechanical design make the V Cone Blender a reliable solution for demanding industrial applications.

laboratory Scale v cone Blender – Machine Video & Product Catalogue

A small V Cone Blender efficiently mixes and blends dry powders and granules for laboratory and R&D applications. Constructed from high-grade stainless steel, it features a dual-cone V-shaped vessel that rotates to create a gentle tumbling action for uniform mixing.

Laboratory models are available in 2 kg, 5 kg, and 10 kg batch capacities, with 6 L, 15 L, and 30 L gross volumes, ensuring thorough blending without dead spots. Its compact design makes it ideal for formulation development, trial batches, and small-batch processing. Equipped with safety interlock systems and easy-to-clean, GMP-friendly internal surfaces, it enhances operational efficiency and product quality. Variable speed control allows precise and repeatable mixing results.

Explore alternative powder mixing solutions based on your process requirements.